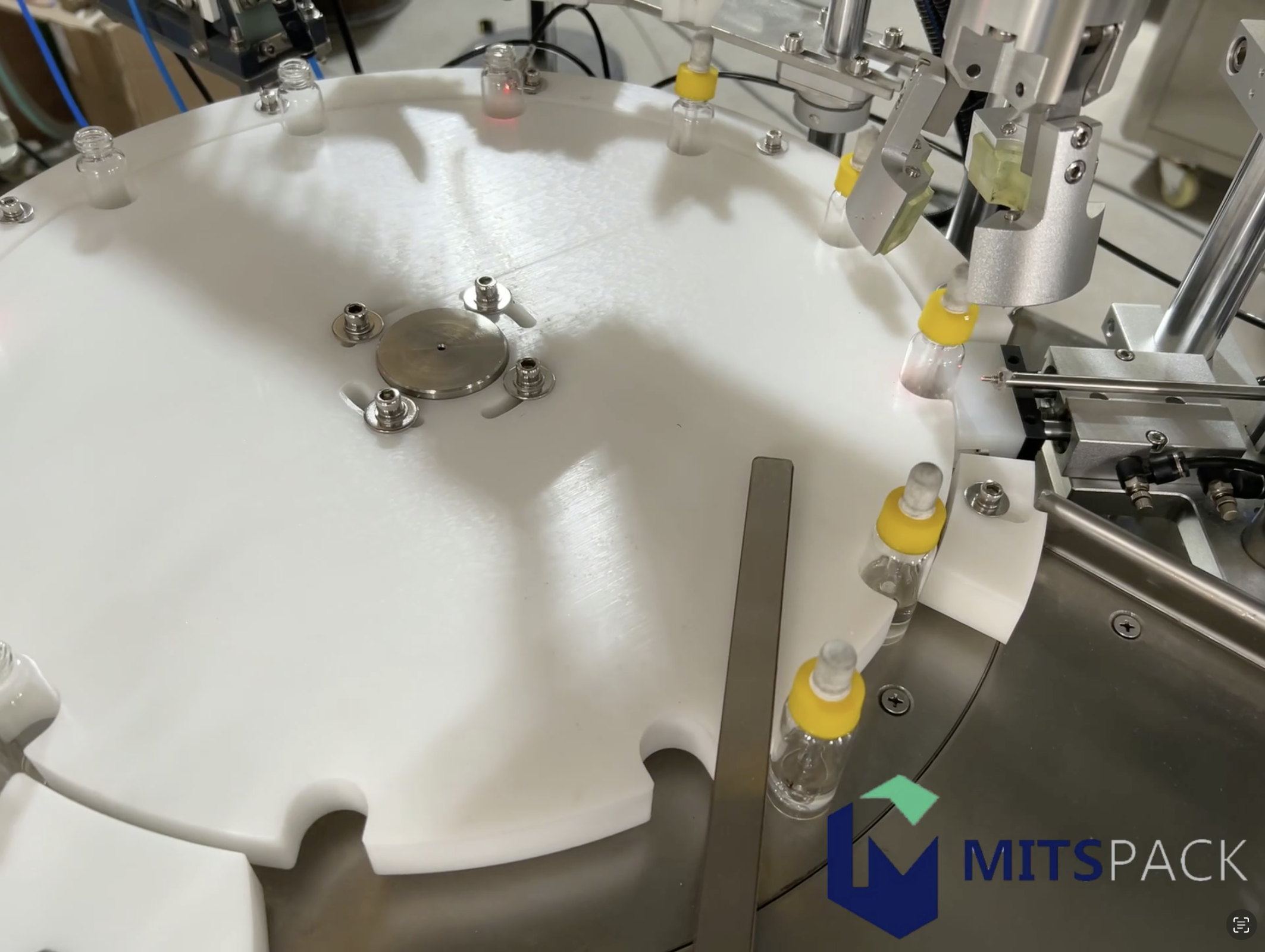

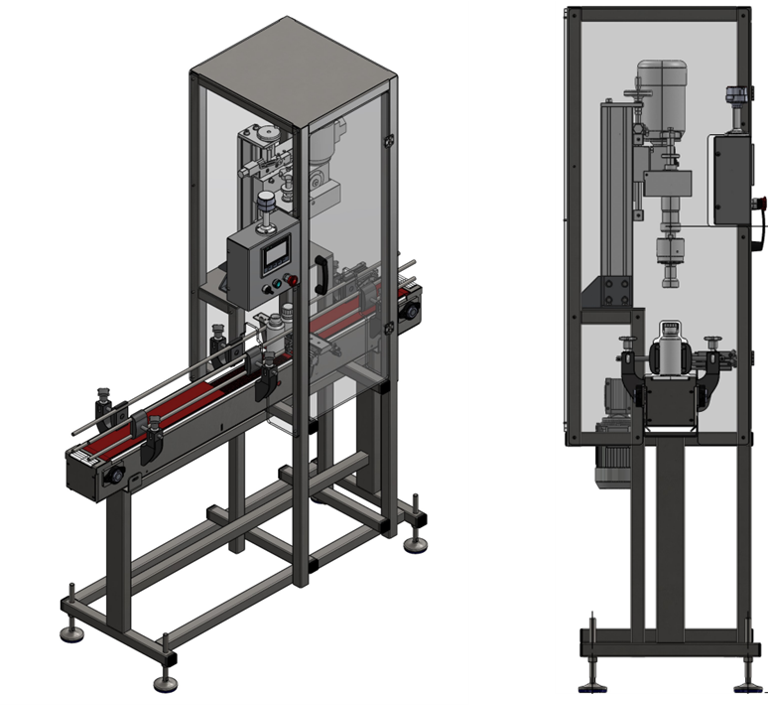

Our screw-capping and closure machines ensure fast, precise, and secure application of caps on all types of containers: bottles, flasks, jars, cans, tubes, and much more. Thanks to their flexible design, they support a wide variety of closure systems

- screw caps,

- snap-on plugs (snap-on),

- dosing capsules,

- pump caps and sprays,

- tamper-evident or secure closures (pharmaceuticals, agri-food),

- pressure or special capsules.

Our equipment can be easily integrated into your packaging lines or operate as stand-alone stations, ensuring consistent, hygienic closure that complies with GMP standards.