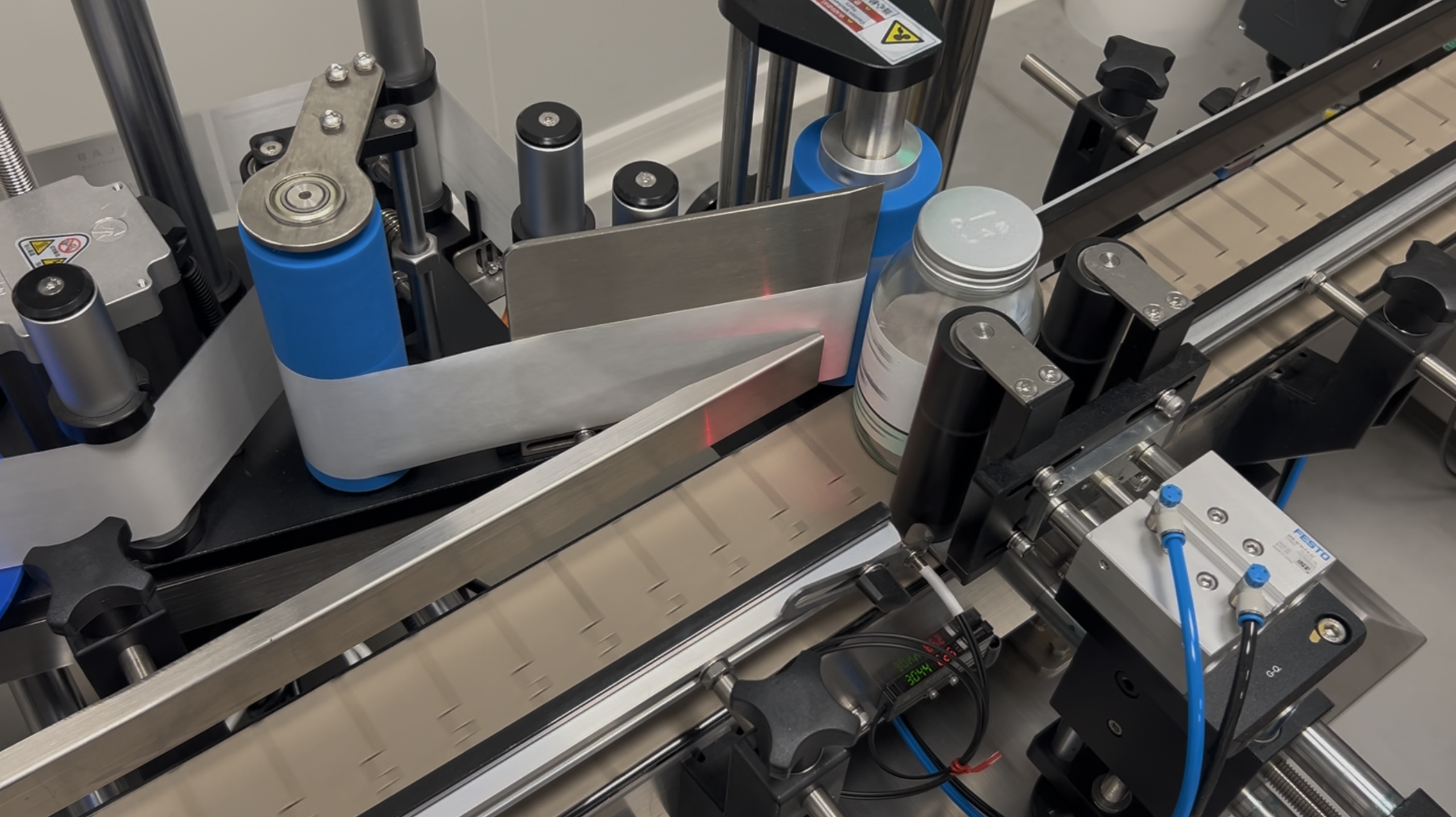

Our industrial labeling machines are designed to accurately apply all types of labels to your products and packaging.

Versatile and adaptable, they can be easily configured to your bottle, flask, carton, tube, sachet, or jar formats, meeting the most stringent requirements in terms of traceability, regulatory compliance, and productivity.

Thanks to integrated serialization systems and high-precision detection sensors, our equipment guarantees fast, uniform, and flawless labeling, ideal for the food, pharmaceutical, cosmetic, and industrial sectors.