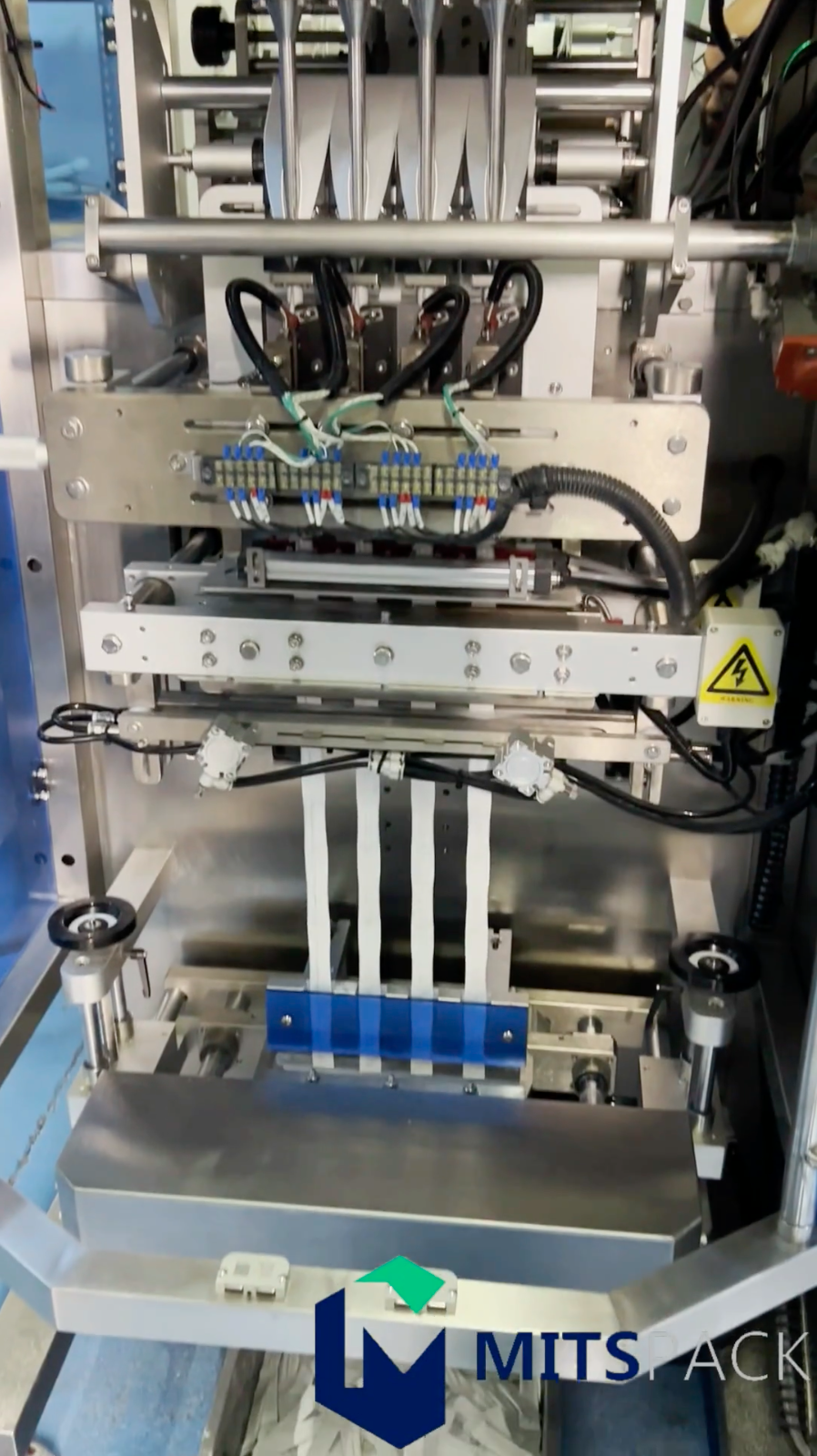

Our powder machines are designed to ensure accurate dosing, hygienic packaging, and efficient handling of all types of powders: pharmaceutical, food, chemical, cosmetic, or industrial.

Whether filling jars, bottles, sachets, capsules, boxes, or big bags, our solutions ensure precision, cleanliness, and productivity. They are equipped with the latest weighing, capping, compaction, and dust control technologies, in full compliance with GMP and ISO standards.