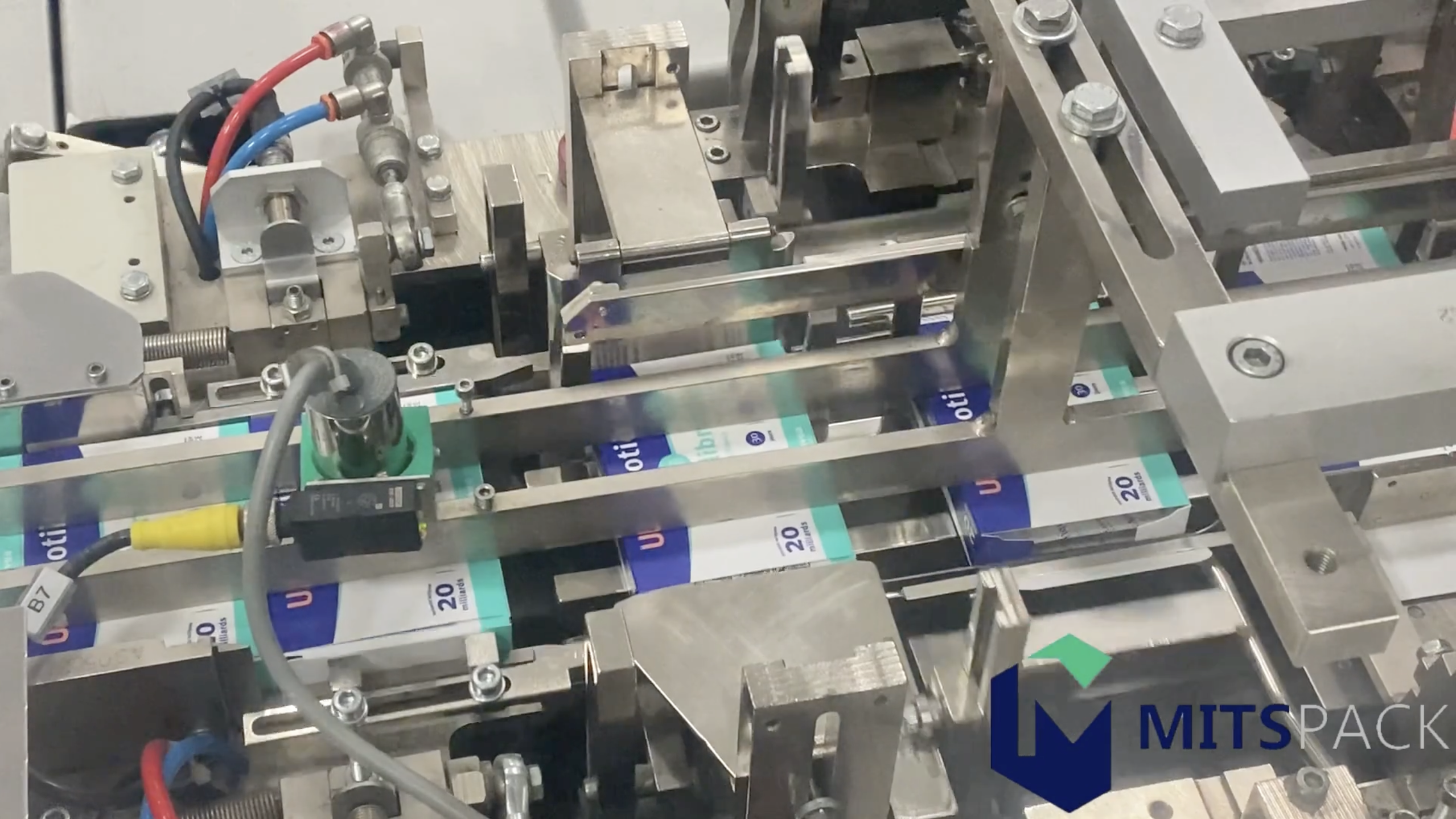

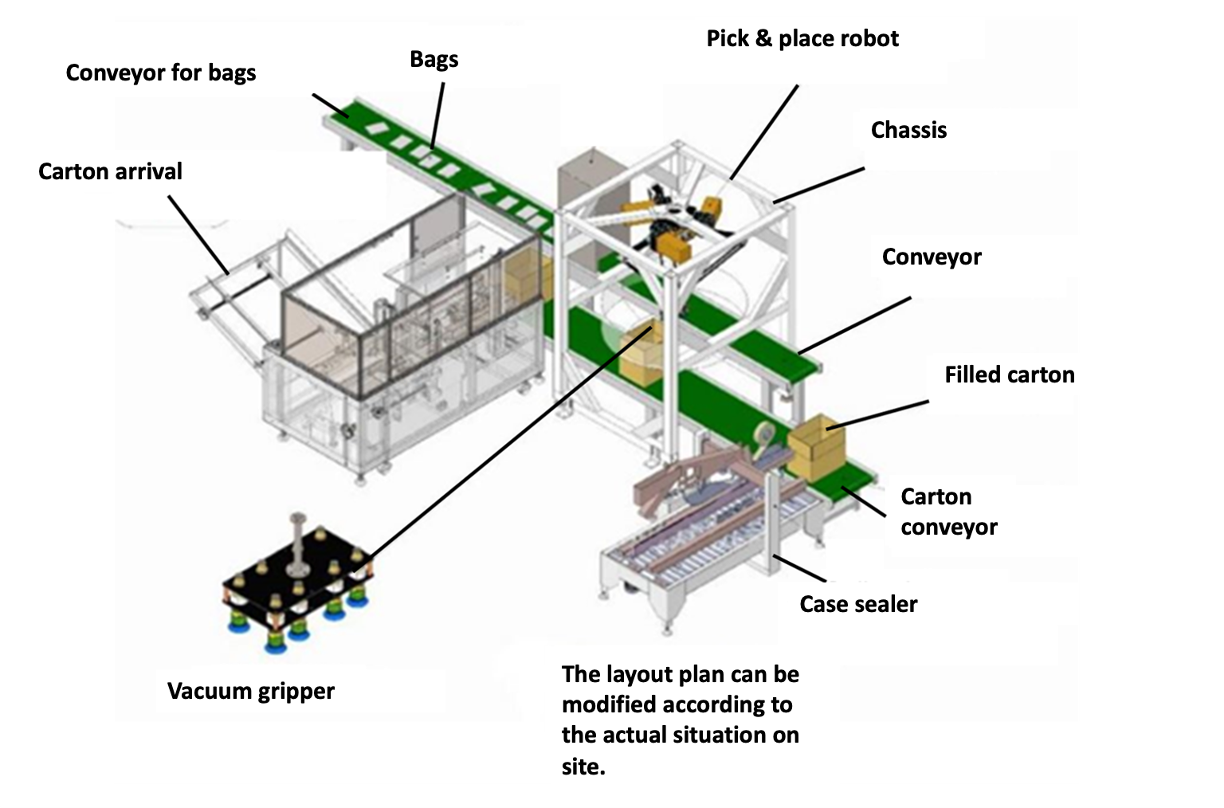

Our cartoning and packaging equipment allows products to be automatically inserted into cartons, boxes, or containers, ensuring accurate and secure final packaging.

Thanks to semi-automatic or fully automatic solutions, we help you increase your productivity, reduce your labor costs, and ensure uniform packaging that complies with GMP standards.